Understanding How a 3D Printer Works in IT Services, Computer Repair, Software Development, and 3D Printing

In today's ever-evolving technological landscape, 3D printing has emerged as a groundbreaking innovation. It has successfully revolutionized numerous industries, including IT Services, Computer Repair, Software Development, and 3D Printing itself. This article will walk you through the intricacies of how a 3D printer operates and shed light on its significance within these domains.

The Basics of 3D Printing

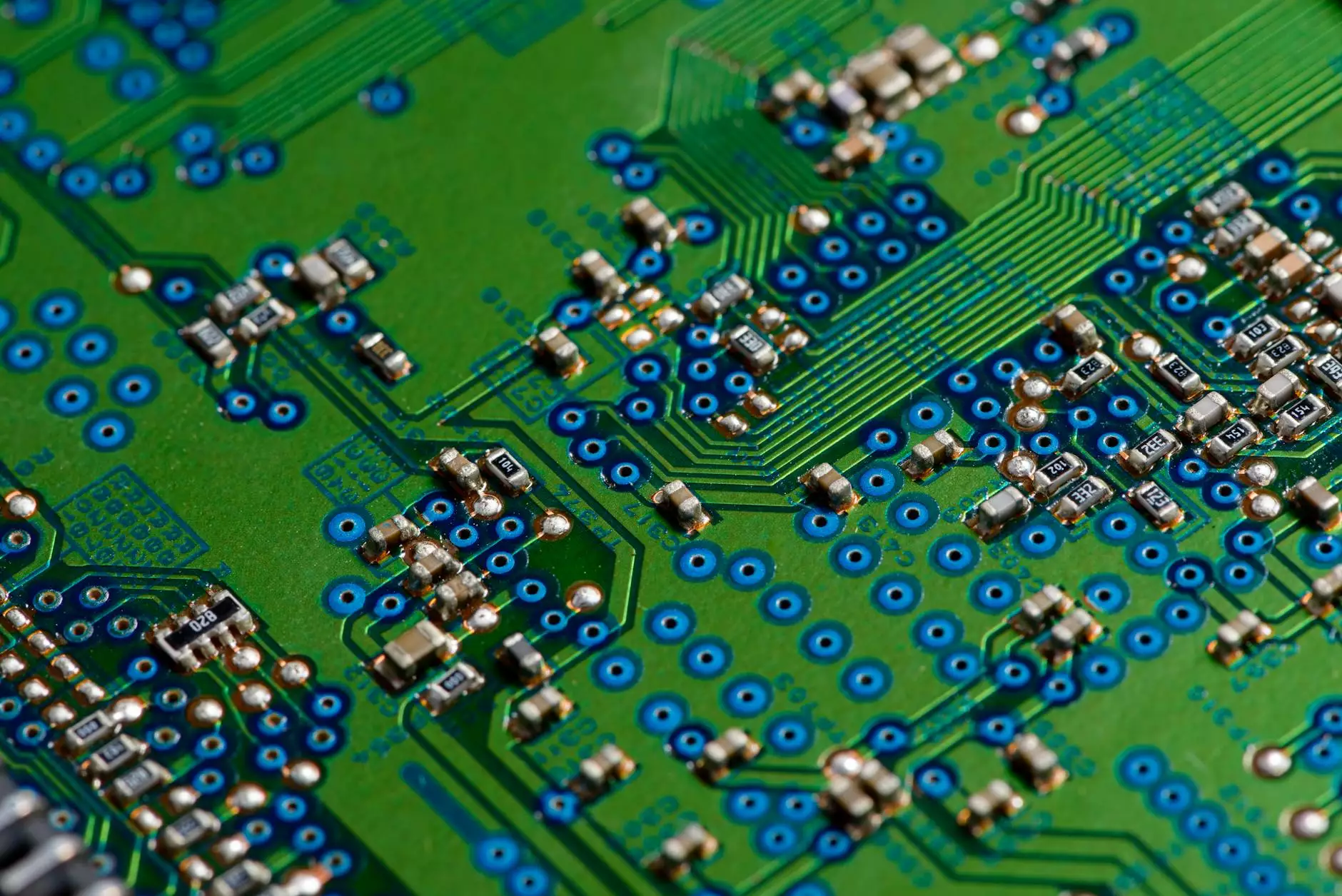

At its core, a 3D printer is a device that can construct three-dimensional objects by adding successive layers of material over one another. This additive manufacturing method sets it apart from traditional subtractive manufacturing techniques. The concept of 3D printing is based on computer-aided design (CAD) models, where a digital model is created and then transformed into a physical object.

Step-by-Step Process of 3D Printing

1. Designing the Model

A 3D printing process begins with designing a 3D model using specialized software. CAD software, such as SelfCAD, allows individuals to create intricate and detailed designs with various features and functionalities. Once the design is finalized, it is ready for the next stage of the process.

2. Preparing the Model for Printing

Before the printing process starts, the 3D model needs to be prepared. This step involves ensuring the file format is compatible with the 3D printer, defining the scale of the object, and optimizing it for printing. Additionally, support structures may need to be added to the model to prevent deformations during the printing process.

3. Slicing the Model

Slicing refers to the process of breaking down the 3D model into a series of thin horizontal layers, almost like slicing a loaf of bread. Each layer is a virtual cross-section of the final object. Slicing software analyzes the model's geometry and generates the instructions required for the 3D printer to construct each layer. These instructions include details on the movement of the print head, temperature settings, and material deposition.

4. Selecting the Printing Material

Choosing the right printing material is crucial to the success of the 3D printing process. Various materials are available, including plastics, resins, metals, ceramics, and even food ingredients. The selection depends on the desired physical properties, durability, and purpose of the end product.

5. Printing the Object

Once the model is prepared, sliced, and the printing material is determined, the 3D printer is ready to commence the object construction. The printer follows the instructions received from the slicing software, precisely depositing the material layer by layer. The printing process can take anywhere from a few minutes to several hours, depending on the complexity and size of the object.

6. Post-Printing Finishing

After the printing process is completed, the resulting object is removed from the printer. Depending on the material used and the desired quality of the final product, additional post-processing steps may be required. These steps may include sanding, polishing, painting, or chemical treatments to achieve the desired appearance and specifications.

Significance in IT Services, Computer Repair, Software Development, and 3D Printing

The impact of 3D printing extends beyond its own industry and is particularly relevant in IT services, computer repair, software development, and of course, 3D printing itself.

In IT services and computer repair, 3D printing allows professionals to rapidly create custom components, spare parts, and prototypes. This reduces the time required for repairs and facilitates the availability of specific components that may no longer be in production.

Software development has greatly benefited from the existence of 3D printers. Developers can create physical prototypes of new products, enhancing their ability to visualize and test designs before investing in mass production. This iterative and cost-effective approach saves time, resources, and ultimately leads to improved final products.

Within the 3D printing industry, the advancement of printer technologies fuels innovation. Continuous improvements in speed, precision, and printable materials open up new possibilities for various applications. Industries such as aerospace, automotive, healthcare, and architecture are integrating 3D printing to achieve remarkable results, including lightweight and intricate structures, personalized medical implants, and sustainable building practices.

The Future of 3D Printing

The future of 3D printing holds tremendous potential. As research and development continue to advance, we can expect even greater innovations and widespread adoption across multiple industries. Improved speed, affordability, and ease-of-use will likely lead to an exponential rise in consumer demand for 3D printers.

The marriage of 3D printing with emerging technologies like artificial intelligence, machine learning, and the Internet of Things will further push the boundaries of what is possible. This fusion will unlock new capabilities, enabling complex designs and smart functionality within printed objects.

Conclusion

Undoubtedly, 3D printing has established itself as a transformative technology within IT Services, Computer Repair, Software Development, and the 3D Printing industry. Its ability to convert digital designs into physical objects has revolutionized numerous sectors, fostering innovation and pushing the boundaries of what is possible. As technology continues to evolve, we eagerly anticipate the remarkable advancements that lie ahead in the world of 3D printing.

how does a 3d printer work